U.S. Army Testing Basketball-Size Inverse-Wankel Rotary Engine; Could Reduce Risk to Troops

Small combustion engine developer LiquidPiston aims to commercialize its XTS-210, a 25-hp, two-stroke, 210-cc rotary engine. The company says that when compared to current diesel piston engines of comparable output, the XTS-210 design "reduces size and weight by nearly 80%." The U.S. Army is hoping that improved design could lead to less casualties on the battlefield.

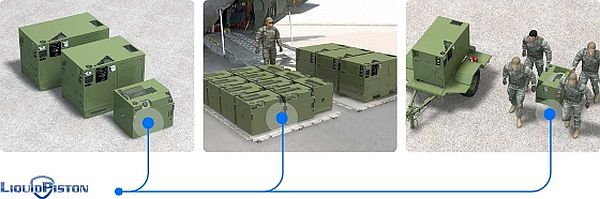

LiquidPiston X-Engine prototypes are claimed to deliver up to 5x the power density of traditional piston diesel engines. [Credit: LiquidPiston]

LiquidPiston recently received a $9 million development contract from the U.S. Army to develop a prototype "core engine" based on the XTS-210 design for military applications. The engine is heavy-fuel compatible (diesel, Jet A, JP-8, kerosene) and multi-fuel capable (gasoline, propane, hydrogen).

Representing the latest generation of LiquidPiston's X-Engine platform architecture, the XTS-210 engine addresses the fuel efficiency, lubrication, and fuel-type limitations of the traditional Wankel rotary engine, an influential engine design developed in the 1950s. The very beginnings of LiquidPiston and its innovative engine trace back all the way to 2003, when it was a "garage" project. To date, the company holds more than 70 patents for the technology.

New XTS-210 engine is the size of a basketball. [Credit: LiquidPiston]

Our sister publication, Designfax, has been following LiquidPiston since 2014 when it was a startup at MIT. Back then, MIT described the novel engine as running "a high-efficiency hybrid cycle (HEHC)" -- developed by Alexander (Alec) Shkolnik (who holds a PhD from MIT) and his physicist father, Nikolay -- "that achieves combustion at constant volume and overexpansion for greater energy extraction. With only two moving parts, a rotor and shaft, and no poppet valves ... the engine also has reduced noise, vibration, and harshness characteristics."

In those early days, a prototype 3.5-hp version -- about as tall as an iPhone 6 -- was considered a great alternative to the small piston-based internal combustion engines used in lawn and garden equipment, particularly because it was so much smaller, lighter, more efficient, quiet, and did not vibrate much.

LiquidPiston X Engine. from LiquidPiston on Vimeo.

In the traditional Wankel engine design, a rounded triangular rotor spins in an eccentric orbit within an oval chamber, with each rotation producing three power strokes -- where the engine generates force. In the LiquidPiston X engine designs, an oval rotor spins within a modified, rounded triangular housing.

LiquidPiston - Intro from LiquidPiston on Vimeo.

According to a LiquidPiston company brochure on the unique engine design, "The X-Engine [development platform] can be likened to an 'inverted' Wankel rotary design, having a trochoidal rotor and three-lobed housing. It leverages a stationary combustion chamber, which enables a higher compression ratio with direct injection of fuel, leading to better efficiency and optimized fuel air mixing. Additionally, stationary apex seals reduce blow-by and offer direct lubrication, improving efficiency, emissions, and durability. The X-Engine has few moving parts and either three or six combustion events per rotor revolution, resulting in very high power density. Except for ancillary parts, there are only two primary moving parts -- the shaft and the rotor -- making the X-Engine simple and elegant in its implementation."

The 25-hp XTS-210 adds up to one bar of boost through supercharging and operates as a two-stroke, producing six combustion events per revolution of the rotor, to deliver smooth power from a lightweight package, roughly the size of a basketball.

The U.S. Army is looking into whether the XTS-210 model can meet demanding commercial and military heavy-fuel applications, including mobile electric power generation, primary or hybrid-electric propulsive power for vertical takeoff and landing aircraft (VTOL) and small unmanned aircraft systems (sUAS), as well as auxiliary power units for land, air, and marine vehicles.

The 25-hp XTS-210 engine core compared to 25-hp Kohler KDW1003. Not shown on the XTS (as the engine is presented here in its preliminary "Alpha" development stage) -- are ancillary systems such as fuel pump, water pump, and oil system. [Credit: LiquidPiston]

According to LiquidPiston, the XTS-210 is unique in its ability to address four major market requirements:

- 5x the power-to-weight (specific power) and power-to-volume (power density), and up to 3x the torque-to-weight (specific torque) compared with diesel piston engines of similar power;

- Ultra-portable and configurable for operation in both engine-only and hybrid-electric modes, and capable of running up to 7,000 RPM, which matches well with small and lightweight electrical machines, enabling increased mobility for power generation and hybrid applications;

- Liquid-cooled and capable of either Spark-Ignition (SI) or Compression-Ignition (CI) -- designed for military-grade robustness from its inception; and

- Multi-fuel capability -- initial testing focuses on JP-8/Jet-A fuels for defense and aerospace applications.

"There are essentially no diesel engines in the 25-horsepower power class today that are suitable for aerospace and mobile military applications, where size and weight parameters are especially critical," said Alec Shkolnik, co-founder and CEO of LiquidPiston. "The reduced weight, size, and heavy- or multi-fuel capability of the XTS-210 delivers significant end-system capability and utility benefits, especially for the military to reduce supply chain and logistical burdens in an era where 'power on the move' is increasingly important."

According to the company, "The X-Engine technology platform is inherently scalable and has been demonstrated to date in engines from 4 to 70 hp."

LiquidPiston is targeting delivery of an XTS-210 prototype to the U.S. Army in 2024. The company has previously prototyped several variants of rotary X-Engines, demonstrating significant versatility in engine architecture, including naturally aspirated four-stroke versions ranging from 5 to 40 hp.

VIDEO: A see-through LiquidPiston rotary engine was built by Warped Perception. [Credit: Warped Perception]

In its bid to revolutionize and downsize battlefield power generation, the U.S. Army is investing the money to try out LiquidPiston's experimental inverse-Wankel rotary engine integrated into a compact 10-kW generator set that is 75% lighter and smaller than currently fielded Advanced Medium Mobile Power Sources.

The LiquidPiston 10-kW Genset, incorporating the XTS-210 X-Engine, is capable of replacing

multiple existing generator power classes with a single genset platform,

greatly simplifying Army genset procurement and logistics. [Credit: LiquidPiston]

According to LiquidPiston, "Current military mobile generators are too heavy and inefficient for modern use cases, which also makes them a potential hazard; during the height of the combat in Iraq and Afghanistan, approximately one-half of American casualties were sustained while moving fuel to the front [Forbes, 2009]. With the power density of LiquidPiston's 10-kW genset, nearly 4x the power could be deployed to the battlefront for the same transport volume as currently fielded gensets; this would reduce the frequency of refueling and therefore the risk to the troops."

The LiquidPiston generator set (genset) will be approximately one-quarter the size and weight of the currently fielded U.S. Army Advanced Medium Mobile Power Source (AMMPS) generator system. Given its smaller footprint and inverter-type operation, LiquidPiston's new genset could replace multiple existing generator power classes with a single genset platform, greatly simplifying military genset procurement and logistics.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::